My experience in vehicle suspension systems and symptoms of bad control arm bushing helped me when I bought a used car. I have taken a quick drive test on smooth and unpaved roads, driving slowly and fast, making turns quickly to check if any noisy sound appears.

Bad control arm bushing consequently has a bad impact on tire tread wear and car performance in general.

Here you will define several signs for bad control arm bushing so that you can easily determine the issue and fix it.

- 3 Main component of control arm bushing:

- Functions of control arm bushing.

- Symptoms of bad control arm bushing.

- Number of control arm bushings and where they are located in the vehicle?

- Causes of worn control arm bushing.

- How to choose suitable control arm bushing?

- Significant best practices to take into consideration.

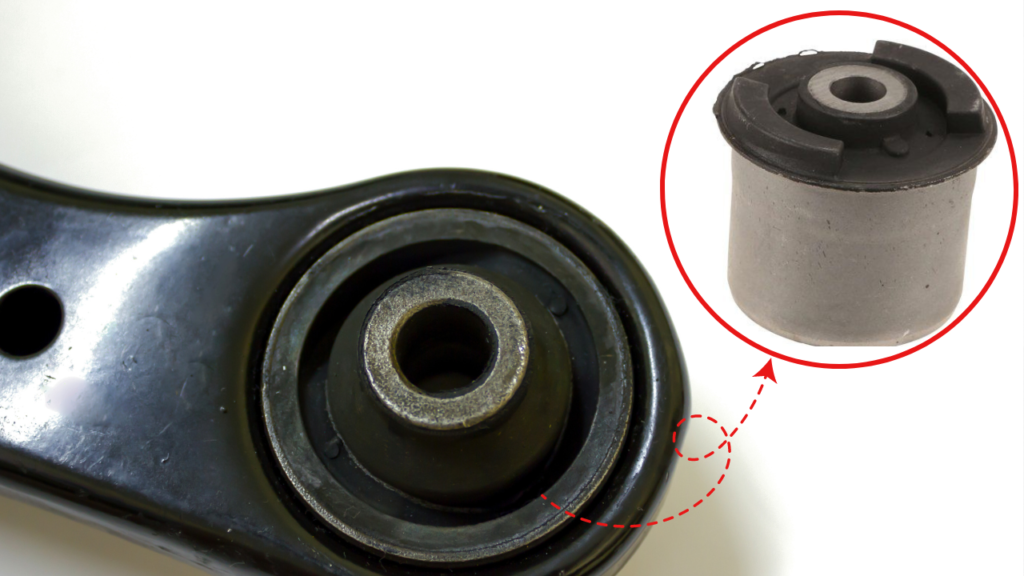

#3 Main component of control arm bushing.

- Outer metal sleeve.

- Durable rubber or polyurethane bushing in the middle.

- Inner metal sleeve.

Functions of control arm bushing.

It is similar to the cartilage of human joints, like a cushion between two metal parts. Control arm bushing has a rubber part that can flex and move while retaining its original shape allowing the wheel to move up and down.

- it plays a significant role in vehicle suspension systems. as it is responsible for connecting the control arm to the vehicle chassis.

- It not only allows the control arm to move smoothly but also helps in absorption of the road vibration while driving particularly on rough roads.

- In small words, control arm bushing isolates the passengers inside the vehicle from (NVH) noise, vibration, and harshness.

Symptoms of bad control arm bushing.

- uneven tire wear: as the control arm bushing wears out over time, it makes the control arm move excessively which results in uneven pressure on the tires and uneven tire wear happens.

- Vibration and shaking: because it is responsible for absorption of the road vibration. if it is in worn condition, it won’t do its function effectively and you will feel vibration in the steering wheel or seats while driving.

- Vibration mainly during braking: bad bushing makes the control arm move aggressively, it can definitely cause wheel misalignment which results in shaking while applying brakes.

- Poor steering response: worn control arm pushing makes it slightly difficult to control the steering wheel and makes your vehicle lean to one side.

- knocking noises: failure of control arm bushing leads to excessive movement of the control arm and metal-to-metal contact happens that results in clunking noises while driving.

- Excessive disturbing of wheel: when you notice the movement of the wheel when it is lifted off the ground, it tells bad control arm bushing.

Number of control arm bushings and where they are located in the vehicle?

- Most vehicles have one or two control arms in both the front and rear suspension system per wheel.

- Each control arm accommodates two bushings.

- Many passenger vehicles have only a lower control arm in the front wheel while trucks or SUV cars always have upper and lower control arms.

How to choose suitable control arm bushing?

OEM (original equipment manufacturer)control arm bushing.

it is designed with reliefs or voids to improve flexibility in one direction however it could cause material tearing and damage.

Aftermarket control arm bushing.

it is manufactured with little or no voids according to vehicle duty. For example: medium duty vehicles require control arm bushing with minimal voids to achieve balance between stiffness and flexibility. and if the vehicle usually carries high load, select the bushing without any voids to decrease wearing out.

- Perfect bushing comes with alignment indicators that make it easy for mechanics to install.

- Control arm bushing comes in two types :

- Rubber bushing: most of the OEM types offer a balance between comfort and durability.

- polyurethane bushings: common in aftermarket with higher responsiveness.

to know more about what OEM stands for you can check [1]

Significant best practices to take into consideration.

- From my experience, the best time to check the control arm bushing or any of the suspension system components is the time for regularly scheduled oil changes.

- If any signs of bad bushing appear in one bushing, it is better to replace them in pairs as the other bushing will be in the same worn condition.

- Sometimes replacing a complete control arm is less expensive than fixing the bushing alone.

- Even if the bushing looks new but comes out of the retainer, you have to fix it immediately to avoid any further complications like replacing the whole control arm.

Causes of worn control arm bushing.

- Age: it is normal for arm bushing to wear out over time as it is made of rubber. It can tear due to the heavy impact of absorption it deals with regularly.

- Heat: high temperature makes arm bushing wear out faster.

- Contamination with road salt or lubricant can cause rubber damage.

- Heavy loads on the vehicle.

- Exposure to harsh environmental conditions.

to wrap up

📛Bad control arm bushing causes the control arm to move excessively and results in noises, shaking and vibration, poor steering response, and uneven tire wear. Check the #6 patterns of uneven tire wear.

3 thoughts on “#6 Symptoms of bad control arm bushing are important to know.”

I like this blog very much, Its a real nice position to read

and find info.Raise range

truly appreciate your comment