- Rubber snap-in valve.

- High-pressure snap-in valve.

- High-pressure metal clamp-in valve.

I have experience of continuous dropping in tire pressure and I figured out the cause of that is damage to the tire valve stem.

I have asked several tire professionals and done intensive research to know about causes, symptoms, and how to replace a tire valve stem myself.

What is the function of the tire valve stem?

What are valve stem parts and types?

What type of tire valve stem should I buy?

How to replace a tire valve stem?

Causes of tire valve stem damage and how to avoid it?

Should I replace the valve stem when I replace vehicle tires?

How much does it cost to replace a tire valve stem?

Should I replace TPMS when I need to replace the valve stem?

What is the function of the tire valve stem?

- It is like an agate through which you can supply or reduce the air inside the tire.

- The Valve stem is mainly used to keep the sealing of the tire and to prevent the air from escaping.

So if there is any damage, cracks, or porous valve stem, slow air leaking happens and so low tire pressure.

So what is the effect of worn tire valve stem on low tire pressure?

- High fuel consumption due to high resistance of the tire on the road.

- Tire wear, damage, or even tire blowout.

- Difficult in handling and steering response.

- Difficult in inflation and deflation tires due to damage or tire valve core.

Through my previous experiences, Consistent dropping in tire pressure without any damage to the tire is frequently due to valve stem leak which must be replaced.

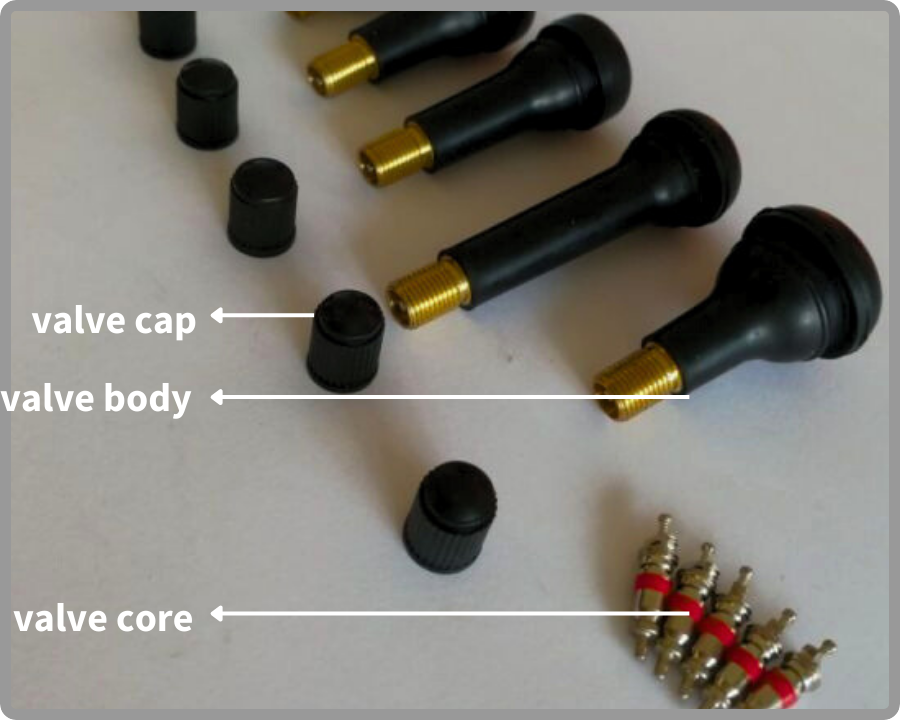

What are tire valve stem parts and types?

The tire valve stem consists of 3 main parts.

- Valve stem body

- it is made of rubber and grooves for cap screwing.

- Valve stem core.

- It looks like a metal pin in the center of the valve body, allows for air passage when you properly depress on it.

- Valve core comes in different lengths while the short valve core is basically for high-speed driving.

- Two types of valve core available in the market.

- Brass valve core

- Nickel valve core compatible with aluminum valve stem since brass core will erode.

- Valve stem cap types.

- Plastic dome. The most common and suitable for normal driving.

- Metal dome. commonly in race track driving to withstand the high temperature.

- Metal screwdriver cap used in removing and inserting valve core.

- Green color valve cap! just indicate the tire is filled with nitrogen.

- Don’t underestimate the importance of the valve cap as it protects the internal part of the valve stem.

In the case of vehicles using wheel covers or with short tire valve, it is difficult to add or check the tire air. I Have solved this issue by using ( valve extension) which increases valve stem length up to 2 inches.

Another trick always works with a short valve stem if I lose valve extension.

- unscrew the valve core slowly with the valve core removal tool.

- Once the air starts to escape, tighten the valve core to stop air loss then connect the inflator with the valve pin.

- After you finish adding air to the tire, retighten the valve core again with a removal tool.

What type of tire valve stem should I buy?

Rubber snap-in tire valve stem.

- Average life span 4-5 years.

- The most common type and ideal for standard use of passenger cars, light-duty trailers, and light trucks.

- Allow max tire pressure up to 65 psi.

- Suitable to fit (0.453 inches) to (0.625 inches) diameter hole in the rim.

- Effective length ranges from (⅞ inches) to (2-½ inches).

High-pressure snap-in tire valve stem.

- Convenient to medium and heavy-duty trucks.

- Allow cold tire pressures that exceed 65 psi.

- Suitable to (0.453 inches) diameter hole for tire pressure 80 psi.

- While those for (0.625 inches) diameter hole for tire pressure 100 psi.

- Effective length ranges from (1-¼ inches) to (2 inches).

High-pressure metal tire valve stem.

- Metal valve lifespan ranges from 5-8 years.

- Made of brass or aluminum to withstand high temperature and pressure.

- Recommended for all race track activities as well as vehicle speeds exceeding 130 mph.

- Allow maximum tire pressure of 200 psi.

- Fit either (0.453 inches) or (0.625 inches) diameter hole.

- Effective length up to 2 inches.

bolt-in tire valve stem

- which is more durable than snap-in valve and is mainly for heavy-duty and off-road vehicles.

Now it is easy for you to select the suitable valve stem based on vehicle type, required tire pressure, and driving condition. Although the valve stem can fit the wheel vertically or horizontally, the vertical alignment is experienced with air escaping at high speeds.

How to replace a tire valve stem?

Check the tire valve stem first before you decide to replace it.

- Pour soapy water on the old valve stem. If you see any generated bubbles, the bad valve stem allows escaping of the tire air.

- Another method, you wiggle the valve stem back and forth. if you hear the sound of air leaking, you have to replace the valve stem.

Replace tire valve stem for a vehicle with no TPMS ( tire pressure monitoring system ). You can replace the valve stem in the tire with no TPMS without breaking the tire bead out of the rim. Using these tools ( tire core removal-hook tool-install tool- plastic funnel)

- Use a tire core removal tool to evacuate the tire from the air.

- Squeeze the hook tool in the valve stem hole in the rim ( between the wheel and valve stem).

- Push the tool in a round direction to pin the inside part of the old valve stem.

- Now you can easily remove the valve stem from the rim.

- Then assemble the install tool. It is a long metal pen, connected to the handle from one end while another end is threaded to a new valve stem.

- Spray some lubricant on the base of the new valve stem.

- Put some lubricant in a plastic funnel. fix the funnel directly over the hole and use it to guide the new valve stem to the wheel hole.

- Insert threaded new valve stem through the funnel and push it toward the rim hole.

- Then by using the assembled handle, gently pull the new valve up till it is properly fitted inside the rim hole.

- Now it is all done, just unscrew the install tool from the new valve.

- check the new valve stem for any air leaking by applying soapy water to ensure there is no coming out of bubbles.

- Once it is ok, adjust your tire pressure.

In the case of a TPMS tire and you want to replace valve stem, you will follow the upcoming steps using these tools (air compressor-jack stand-lug nut wrench-sledgehammer-valve core removal tool)

- Remove the wheel from the vehicle using a nut wrench and jack stand.

- Place the wheel on the ground flat while outside of the wheel facing up.

- Use a tire core removal tool to remove the valve core and evacuate the tire from the air.

- Wear safety glasses to protect your eyes from any volatile debris.

- Now, separate the tire bead from the wheel.

- Put a wooden block over the tire sidewall.

- Place the scissor jack over the wood and raise it till it reaches the vehicle lift point.

- Continue raising until breaking the tire bead.

- You can use a sledgehammer or any method to break the tire bead.

- My practical advice is you don’t necessarily need to completely remove the tire out of the wheel. Breaking the tire bead is enough.

- Now you can cut the inner part of the valve stem and gently free the defective valve stem from the wheel.

- I prefer to clean any deposits and rust remaining before installing a new valve.

- Apply some lubricant to the new valve stem base and install it inside the hole from the inner side.

- use the stem holder (39 bucks cost ) from the outer side to slightly pull the stem valve and properly fit it inside the hole.

- Fill the tire with air till you hear the popping sound of tire bead back on.

- check the new valve stem for any air leaking by applying soapy water to ensure there is no coming out of bubbles.

- Once it is ok, adjust your tire pressure.

- Sometimes, all you need is to replace the tire valve core only instead of replacing the entire valve stem, so check the valve core first.

Causes of tire valve stem damage and how to avoid it?

- A number of reasons that make the tire valve worn.

- The main component of tire valve stem is rubber which over time becomes brittle, cracked, and loses its sealing properties.

- Environmental contaminants like dirt, and debris prevent the valve core from sealing completely.

- Water exposure can freeze in cold temperatures and obstruct the seal.

- Road chemicals like road salt

- Dislocation of the tire valve might happen when aggressively inflating the tire.

- Improper tire valve installation.

- How to protect the valve stem from damage?

- The main advice I often follow is to keep the valve cap. importance of the valve stem cap.

- stem cap not only protects the tire valve core from moisture and debris but also prevents air from escaping in case of valve core disruption. ( act as backup sealing)

- Check or inflate the tire pressure away from the middle snowstorm to avoid moisture contamination.

- If you lose the valve cap and want to adjust tire pressure, I have experience of pressing the valve core momentarily to release little air that bounces any debris out.

Should I replace the valve stem when I replace vehicle tires?

- No, it should not, but from my practical point of view, I recommend replacing the tire valve stem at the same time as replacing vehicle tires. why?

- Old valve stem cannot withstand for a longer time to match the tire life span. so it is better to avoid the hassle of valve replacement in the middle of the tire’s lifetime.

- If you want to keep the old valve stem with new tires, try to make a quick visual inspection of the valve stem during routine tire maintenance.

How much does it cost to replace a tire valve stem?

- Average price for a tire valve stem is about 5 dollars for each.

- Average labor cost for valve stem replacement is 7-10 dollars for each

- Total cost to replace the tire valve stem ranges from 11-16 dollars.

- Valve stems with TPMS installations are merely 25 or 30 dollars.

- Rubber snap-in valve is about 3 dollars per pack.

- High pressure snap-in valve is about 9 dollars per pack.

- Metal valve stem is about 7 dollars per pack.

Should I replace TPMS when I need to replace the valve stem?

- Definitely not. The new TPMS sensor comes with a new valve stem but the new valve stem does not require a new TPMS sensor.

- TPMS can easily transfer to the new valve stem.

- Please note that if you want to replace the valve stem for TPMS tire, you will need to purchase a special rubber snap-in or metal clamp-in valve to anchor the TPMS sensor.

- TPMS valve stem is more expensive and requires activation with OBD2 software. So my advice is to get help from a tire shop to do this mission.

The bottom line.

Now you understand how valve stem damage causes a lowering in tire pressure so TPMS light on.

Check when you have to replace the TPMS sensor now.

6 thoughts on “What are tire valve stem types? and how you can easily replace it yourself.”

I wanted to thank you for this great read!! I definitely enjoying every little bit of it I have you bookmarked to check out new stuff you post…

Thanks for your fine words, hoping to always get your satisfaction .

I’m impressed, I need to say. Really rarely do I encounter a blog that’s both educative and entertaining, and let me tell you, you will have hit the nail on the head. Your concept is outstanding; the difficulty is something that not sufficient individuals are speaking intelligently about. I am very comfortable that I stumbled throughout this in my search for one thing regarding this.

happy that you find it valuable, thank you very much.

Definitely, what a great blog and enlightening posts, I definitely will bookmark your blog.Best Regards!

It?¦s in reality a nice and useful piece of info. I am satisfied that you simply shared this useful information with us. Please stay us up to date like this. Thanks for sharing.